I've seen a lot of Q&A session on the backorder processing and rescheduling and would like to discuss the backorder processing in this blog and would write up a follower for rescheduling.

Backorder processing as the name specifies is allocation and confirmation of quantity that has NOT been confirmed to a customer order prior, mainly due to absence of stock. Using Backorder processing, we could also override the quantities confirmed via "Product Allocation".

Rescheduling on the other hand is to remove already confirmed quantities of a customer order and reallocate it to another priority customer, which could also be due to shortage of stock .

Note: The key configuration necessary for Backorder processing is the “Checking Rule for Updating Backorders”. The checking rule is determined based on the availability check maintained in the Material Master – Sales/General Plant tab per client requirements.

1.

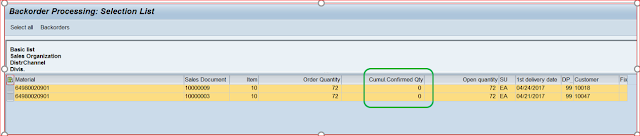

Execute Transaction Code V_RA – Backorder scheduling. Note below that the cumulative

confirmed quantity is Zero for both orders.

3. Select the line which want to allocate and confirm quantities. We could also select all the lines by clicking “Select all” button.

4. The selected line will be in blue in the below screen. Select the line and Click “Change Confirmation" at the top.

5. Enter

the quantity you want to confirm in the ‘Committed” field at the bottom left

screen.

Note: Click on the Back icon on the screen and the system will prompt to “Copy the confirmation” and Click the Yes button.

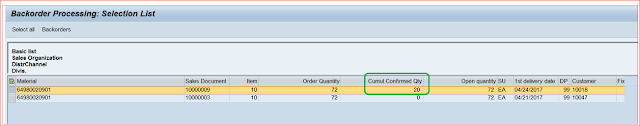

6. On Clicking the Yes button, the confirmation quantity is copied to the order line. Note the cumulative confirmed qty has been changed to 20.

7. Open

the order and check the schedule lines, and you should notice the order has

been for 72 qty and confirmed for 20. The remaining 52 qty will still be on

backorder.