It's a known fact that if you enter the delivery block at header level, the system transfers the

desired delivery quantity for all schedule lines in the requirement routine for Availability Check and the

confirmed quantity is deleted, example Orders blocked for Credit Checks.

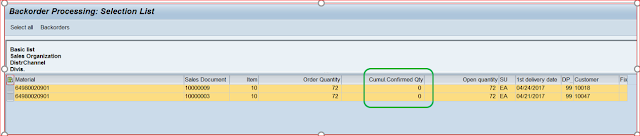

The same function is not available when the delivery block is set at schedule line level. This business scenario can only be achieved via custom development. SAP has provided an Enhancement 'ATP00001' which composes of two Function Exits. The user exit is triggered during order and delivery processing and implement this enhancement via CMOD. Use Function Exit EXIT_SAPLATPC_002, to clear/block the confirmation quantities when the order line item is blocked at schedule line level.

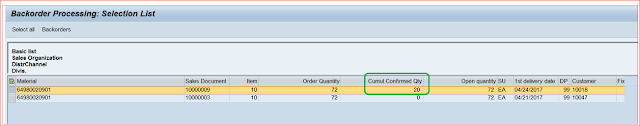

Note: Removal of the delivery block at the schedule line does not automatically confirm the line item quantities, the confirmation of the lines should be handled using the Backorder processing (TCode : V_RA). Please check my earlier blog on Backorder processing

Regards,

[V]

The same function is not available when the delivery block is set at schedule line level. This business scenario can only be achieved via custom development. SAP has provided an Enhancement 'ATP00001' which composes of two Function Exits. The user exit is triggered during order and delivery processing and implement this enhancement via CMOD. Use Function Exit EXIT_SAPLATPC_002, to clear/block the confirmation quantities when the order line item is blocked at schedule line level.

Note: Removal of the delivery block at the schedule line does not automatically confirm the line item quantities, the confirmation of the lines should be handled using the Backorder processing (TCode : V_RA). Please check my earlier blog on Backorder processing

Regards,

[V]